Cable Clamps Cleats

- About Cable Clamps / Cleats

- HV Single Cable Clamp

- HV Trefoil Cable Clamps

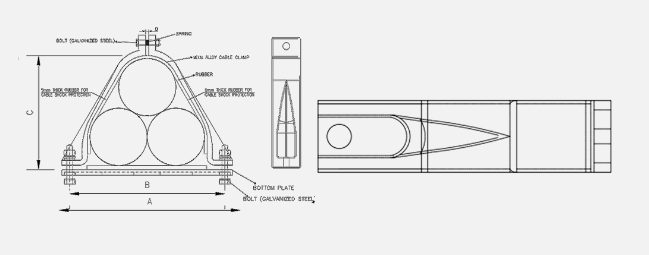

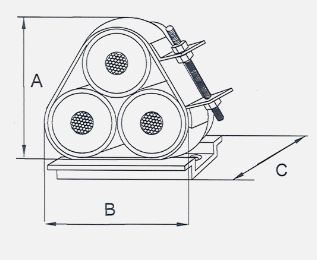

- HV/MV Trefoil SS Cable Clamps

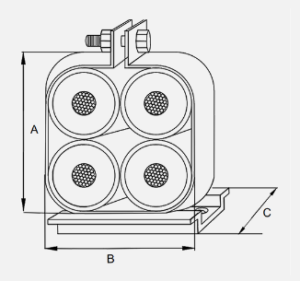

- HV/MV Quad SS Cable Clamps

- HV/MV Single Bolt SS Cable Clamps

- MV/LV Trefoil AI Cable Clamps

- MV/LV Trefoil SS Cable Clamps

- Download Catalogue

Cable clamp/cleat is a device designed to provide securing of cables when installed at intervals along the length of the cables.” (IEC 61914). PTE's single & trefoil clamps made of non-ferrous, non-magnetic alloys meets the requirement of latest international standards & type tested for electrical short circuit, axial load, lateral load and impact as per stringent requirements of IEC 61914.

Our clamps are provided with all the required installation hardware, like nuts, bolts, washers, and springs. EPDM rubber lining is used with the clamps to increase friction resistance, & to accommodate the expansion of XLPE during heating/cooling cycles due to varying loads& ambient temperature variations.

Cable clamps are designed to hold cables in Flat and trefoil formation in normal operating conditions and restore cable geometry after experiencing severe loads & short circuit which may result in damage of terminations/sealing ends.

Selection of right clamps with adequate strength is the most important factor to overcome a fault and enable the circuit to be restored once the fault has been repaired. The proper clamping is important ensures easy installation and the safe long term performance of the cable system.

When parallel conductors carrying 3 phase alternating current suffer a short circuit fault, the cables experiencing extreme opposing forces. Hence it is very important to have a proper cable support and clamps design to ensure the safety of cable at transient switching and faults.

Technical Data & Classification

| Type | Aluminium Single |

|---|---|

| Design Specification | IEC 61914:2015 |

| Maximum Operating Temprature in degree C | *-50°C to +160°C IEC 61914:2015 |

| Short Circuit withstand rating. | 66 kA/sec, as per IEC-61914:2015 Clause 9.5.2 |

| Short Circuit Peak Current | 167.3 kA as per IEC-61914:2015 Clause 9.5.2 |

| Impact Test | Very Heavy as per IEC 61914:2015 |

| Axial Load Test | 255 kgf |

| Lateral Load | 1530 ≤ 2040 kgf |

| Material | Cast Aluminium Alloy |

| Material Colour | Silver |

| Catalogue # | Cable Diameter Range (mm) | Dimensions | Clamp Weight | |||

|---|---|---|---|---|---|---|

| A | B | C | D | |||

| PTE-DC-94 | 79-91 | 143 | 123 | 109 | 70 | 178 |

| PTE-DC-108 | 92-106 | 158 | 133 | 122 | 58 | 1050 |

| PTE-DC-122 | 107-120 | 176 | 151 | 138 | 65 | 1200 |

| PTE-DC-134 | 121-133 | 194 | 166 | 155 | 71.42 | 1600 |

| PTE-DC-148 | 134-147 | 214 | 184 | 167 | 78 | 1900 |

| PTE-DC-165 | 148-163 | 238 | 209 | 186 | 83.5 | 2700 |

| Catalogue # | Cable Diameter Range (mm) | Dimensions | Clamp Weight | |||

|---|---|---|---|---|---|---|

| A1 | B1 | C1 | D1 | |||

| PTE-DC-66 | 50-64 | 104 | 79 | 73 | 38 | 600 |

| PTE-DC-77 | 64-76 | 122 | 97 | 89 | 44.5 | 700 |

Technical Data & Classification

| Type | Aluminium Trefoil |

|---|---|

| Design Specification | IEC 61914:2015 |

| Maximum Operating Temprature in degree C | *-50°C to +160°C IEC 61914:2159 |

| Short Circuit withstand rating. | 65 kA/sec, as per IEC-61914:2015 Clause 9.5.2 |

| Short Circuit Peak Current | 94 kA as per IEC-61914:2015 Clause 9.5.2 |

| Impact Test | Very Heavy as per IEC 61914:2015 |

| Axial Load Test | 240 kgf |

| Lateral Load | 1530 kgf |

| Material | Cast Aluminium Alloy |

| Material Colour | Silver |

| Catalogue # | Cable Diameter Range (mm) | Dimensions | Clamp Weight | |||

|---|---|---|---|---|---|---|

| A | B | C | D | |||

| PTE-TC-108 | 84-100 | 320 | 265 | 213 | 5-28 | 178 |

| PTE-TC-119 | 101-117 | 360 | 300 | 243 | 5-28 | 1050 |

| PTE-TC-134 | 118-134 | 400 | 335 | 272 | 5-28 | 1200 |

| PTE-TC-150 | 135-150 | 440 | 370 | 302 | 5-28 | 1600 |

| PTE-TC-166 | 151-166 | 480 | 405 | 332 | 5-28 | 1900 |

Technical Data Classification

| Type | SS TREFOIL |

|---|---|

| Design Specification | IEC 61914:2009 |

| Temperature for permanent application | *-50°C to +160°C IEC 61914:2009 clause / part 6.2 & Local Standards. |

| Lateral Load Capability | 22kN Perpendicular to the Installation Axis 22kN Horizontal to the Installation Axis, IEC 61914:2009 clause 9.3 |

| Axial Load Capability | 2.5kN IEC 61914:2009 clause 9.4, |

| Impact Resistance | Very Heavy as per IEC 61914:2009 clause 6.3, 6.3.5, 9.2 |

| Material | 316L Stainless Steel Strap with Standard Liner |

| Material Colour | Silver / Grey |

| Catalogue # | Cable Diameter Range (mm) | Dimensions | Clamp Weight | ||

|---|---|---|---|---|---|

| A | B | C | |||

| PTE-TC-SS-34 | 24-34 | 73 | 67 | 80 | 178 |

| PTE-TC-SS-41 | 30-41 | 87 | 81 | 80 | 187 |

| PTE-TC-SS-47 | 37-47 | 97 | 93 | 80 | 210 |

| PTE-TC-SS-54 | 43-54 | 113 | 106 | 80 | 225 |

| PTE-TC-SS-60 | 50-60 | 125 | 118 | 80 | 235 |

| PTE-TC-SS-67 | 57-67 | 139 | 131 | 80 | 260 |

| PTE-TC-SS-73 | 63-73 | 151 | 142 | 80 | 270 |

| PTE-TC-SS-80 | 69-80 | 165 | 156 | 80 | 295 |

| PTE-TC-SS-85 | 72-85 | 175 | 165 | 80 | 300 |

| PTE-TC-SS-95 | 82-95 | 195 | 185 | 80 | 325 |

| PTE-TC-SS-105 | 92-105 | 215 | 204 | 80 | 350 |

| PTE-TC-SS-115 | 102-115 | 235 | 223 | 80 | 380 |

| PTE-TC-SS-125 | 122-125 | 255 | 243 | 80 | 410 |

| PTE-TC-SS-135 | 122-135 | 275 | 262 | 80 | 430 |

| PTE-TC-SS-145 | 132-145 | 295 | 281.5 | 80 | 460 |

Technical Data Classification

| Type | SS QUAD |

|---|---|

| Design Specification | IEC 61914:2009 |

| Temperature for permanent application | *-50°C to +60°C IEC 61914:2009 clause / part 6.2 & Local Standards. |

| Lateral Load Capability | 22kN Perpendicular to the Installation Axis 22kN Horizontal to the Installation Axis, IEC 61914:2009 clause 9.3 |

| Axial Load Capability | 2.5kN IEC 61914:2009 clause 9.4, |

| Impact Resistance | Very Heavy as per IEC 61914:2009 clause 6.3, 6.3.5, 9.2 |

| Material | 316L Stainless Steel Strap with Standard Liner |

| Material Colour | Silver / Grey |

| Catalogue # | Cable Diameter Range (mm) | Dimensions | Clamp Weight | ||

|---|---|---|---|---|---|

| A | B | C | |||

| PTE-QC-SS-34 | 21-27 | 100 | 65 | 80 | 178 |

| PTE-QC-SS-41 | 25-31 | 110 | 73 | 80 | 187 |

| PTE-QC-SS-47 | 30-35 | 115 | 79 | 80 | 210 |

| PTE-QC-SS-54 | 34-37 | 120 | 85 | 80 | 225 |

| PTE-QC-SS-60 | 36-40 | 130 | 90 | 80 | 235 |

| PTE-QC-SS-67 | 39-45 | 135 | 95 | 80 | 260 |

| PTE-QC-SS-73 | 44-47 | 140 | 100 | 80 | 270 |

| PTE-QC-SS-80 | 46-50 | 145 | 105 | 80 | 295 |

| PTE-QC-SS-85 | 49-55 | 150 | 110 | 80 | 300 |

| PTE-QC-SS-95 | 54-60 | 155 | 115 | 80 | 325 |

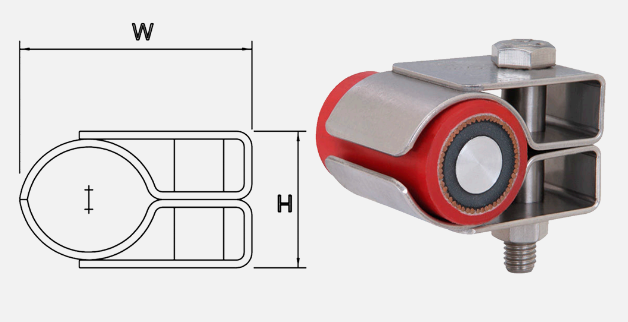

Technical Data Classification

| Type | SS CLAW |

|---|---|

| Design Specification | IEC 61914:2009 |

| Temperature for permanent application | *-50°C to +160°C IEC 61914:2009 clause / part 6.2 & Local Standards. |

| Lateral Load Capability | 22kN Perpendicular to the Installation Axis 22kN Horizontal to the Installation Axis, IEC 61914:2009 clause 9.3 |

| Axial Load Capability | 2.5kN IEC 61914:2009 clause 9.4, |

| Impact Resistance | Very Heavy as per IEC 61914:2009 clause 6.3, 6.3.5, 9.2 |

| Material | 316L Stainless Steel Strap with Standard Liner |

| Material Colour | Silver / Grey |

| Model Code | Diameter Min-Max | W | H |

|---|---|---|---|

| PTE-DC-SS-20 | 20 - 26 | 51 | 31 |

| PTE-DC-SS-25 | 25 - 31 | 55 | 35 |

| PTE-DC-SS-30 | 30 - 36 | 60 | 40 |

| PTE-DC-SS-35 | 35 - 41 | 66 | 46 |

| PTE-DC-SS-40 | 40 - 46 | 74 | 54 |

| PTE-DC-SS-45 | 45 - 51 | 80 | 59 |

| PTE-DC-SS-50 | 50 - 56 | 85 | 64 |

| PTE-DC-SS-55 | 55 - 61 | 93 | 73 |

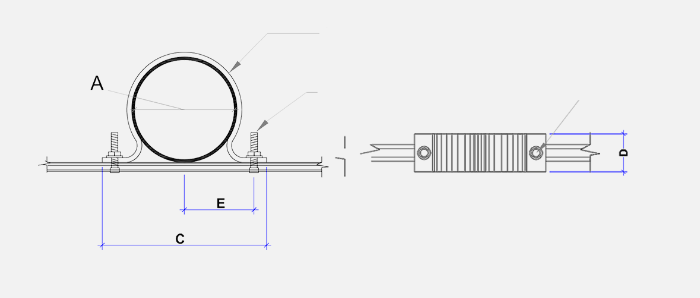

Technical Data Classification

| Catalogue # | Cable Diameter A (mm) | Dimensions | Stud Size | |||

|---|---|---|---|---|---|---|

| Min | Max | C | D | E | ||

| PTE-DC- 25 | 25 | 29 | 129 | 50 | 84 | M10 |

| PTE-DC- 30 | 30 | 34 | 134 | 50 | 88 | M10 |

| PTE-DC- 35 | 35 | 39 | 139 | 50 | 92 | M10 |

| PTE-DC- 40 | 40 | 44 | 144 | 50 | 96 | M10 |

| PTE-DC- 45 | 45 | 49 | 149 | 50 | 100 | M10 |

| PTE-DC- 50 | 50 | 54 | 154 | 50 | 104 | M10 |

| PTE-DC- 55 | 55 | 59 | 159 | 50 | 109 | M10 |

| PTE-DC- 60 | 60 | 64 | 164 | 50 | 114 | M10 |

| PTE-DC- 65 | 65 | 69 | 169 | 50 | 119 | M10 |

| PTE-DC- 70 | 70 | 74 | 174 | 50 | 124 | M10 |

| PTE-DC- 75 | 75 | 79 | 179 | 50 | 129 | M10 |

| PTE-DC- 80 | 80 | 84 | 184 | 50 | 134 | M10 |

| PTE-DC- 85 | 85 | 89 | 189 | 50 | 139 | M10 |

| PTE-DC- 90 | 90 | 94 | 194 | 50 | 144 | M10 |

| PTE-DC- 95 | 95 | 99 | 199 | 50 | 149 | M10 |

| PTE-DC- 30 | 100 | 104 | 204 | 50 | 154 | M10 |

| PTE-DC- 30 | 105 | 109 | 209 | 50 | 159 | M10 |

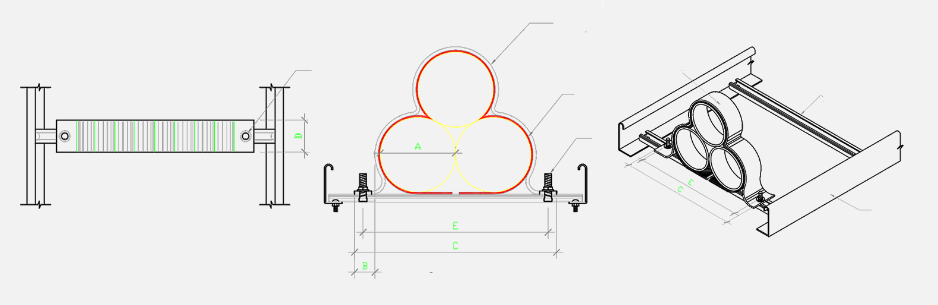

Technical Data Classification

| Model No. | Item | Cable Diameter (A) mm | Dimensions | Stud Size | |||

|---|---|---|---|---|---|---|---|

| Min | Max | C | D | E | |||

| PTE-TC-20 | 1 | 20 | 24 | 150 | 30 | 100 | M10 |

| PTE-TC-25 | 2 | 25 | 29 | 160 | 30 | 110 | M10 |

| PTE-TC-30 | 3 | 30 | 34 | 170 | 30 | 120 | M10 |

| PTE-TC-35 | 4 | 35 | 39 | 180 | 30 | 130 | M10 |

| PTE-TC-40 | 5 | 40 | 44 | 190 | 30 | 140 | M10 |

| PTE-TC-45 | 6 | 45 | 49 | 200 | 30 | 150 | M10 |

| PTE-TC-50 | 7 | 50 | 54 | 210 | 40 | 160 | M10 |

| PTE-TC-55 | 8 | 55 | 59 | 220 | 40 | 170 | M10 |

| PTE-TC-60 | 9 | 60 | 64 | 230 | 40 | 180 | M10 |

| PTE-TC-65 | 10 | 65 | 69 | 240 | 40 | 190 | M10 |

| PTE-TC-70 | 11 | 70 | 74 | 250 | 40 | 200 | M10 |

| PTE-TC-75 | 12 | 75 | 79 | 260 | 40 | 210 | M10 |

| PTE-TC-80 | 13 | 80 | 84 | 290 | 50 | 230 | M12 |

| PTE-TC-85 | 14 | 85 | 89 | 300 | 50 | 240 | M12 |

| PTE-TC-90 | 15 | 90 | 94 | 310 | 50 | 250 | M12 |

| PTE-TC-95 | 16 | 95 | 99 | 320 | 50 | 260 | M12 |

| PTE-TC-100 | 17 | 100 | 104 | 330 | 50 | 270 | M12 |

| PTE-TC-105 | 18 | 105 | 109 | 340 | 50 | 280 | M12 |

| PTE-TC-110 | 19 | 110 | 114 | 350 | 50 | 290 | M12 |

| PTE-TC-115 | 20 | 115 | 119 | 360 | 50 | 300 | M12 |

| PTE-TC-120 | 21 | 120 | 124 | 370 | 50 | 310 | M12 |

| PTE-TC-125 | 22 | 125 | 129 | 380 | 50 | 320 | M12 |

| PTE-TC-130 | 23 | 130 | 134 | 390 | 50 | 330 | M12 |

| PTE-TC-135 | 24 | 140 | 144 | 400 | 50 | 340 | M12 |